At the bend of the aisles of the Mondial du Chocolat et du Cacao, we happily go from Ivory Coast to Peru, from Brazil to New Zealand, from Madagascar to Hawaii, while tasting an infinite variety of chocolates, each with its own flavor particular.

Exotic journey but also olfactory and gustatory.

It’s a bit like wines. We first smell the aromas, appreciate the color, then we taste, slowly, deliciously. Chocolate also has its pure origin grands crus, made up of cocoa from a single country and its blended vintages, an alliance of cocoas from different origins chosen for their complementarity.

Also a fantastic and mysterious journey.

What are the steps required to make chocolate?

They are many !

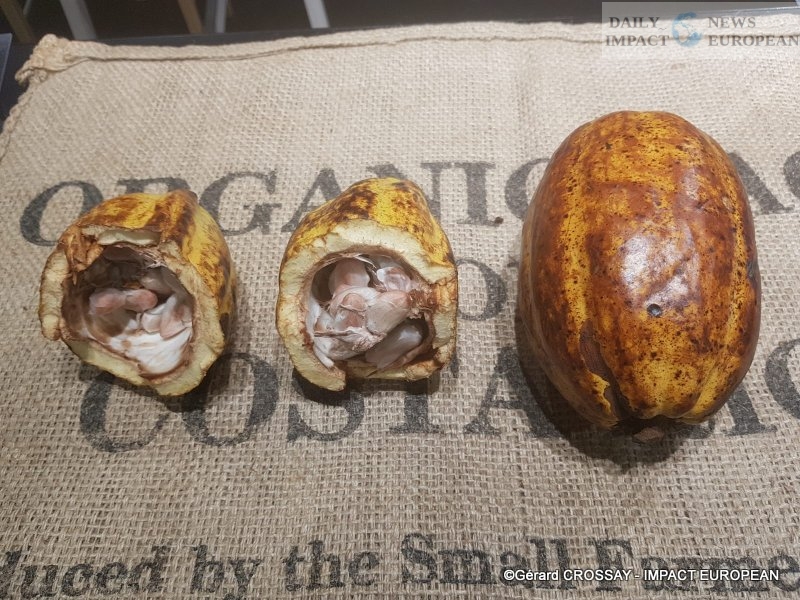

We first harvest the “pods”, fruits of the cocoa tree, a tree which only grows between the Tropic of Cancer and the Tropic of Capricorn. Originally cultivated in Mexico, it is now found in other countries in South America, in Asia and especially in West Africa, an area covering 70% of world production.

Then comes “shelling”, which consists of splitting the pod in two to extract the seeds which will then be stored in large wooden baskets for a week for fermentation.

They must then be dried for two weeks in full sun.

They are then exported to consuming countries where these beans are roasted, that is to say grilled between 100 and 140°C.

There is also low temperature roasting which would preserve the qualities of cocoa and its richness in antioxidants, making it possible to obtain “raw chocolate”. According to some, this would be a “super health food”,

reducing bad cholesterol, preventing certain forms of cancer, improving blood circulation and protecting against cardiovascular diseases…

Not to be confused with 100% dark chocolate, with a very powerful taste, which contains no added sugar, excellent for mood and health.

So, fermentation, drying, roasting… grinding of the beans to obtain the « cocoa mass », which is compressed, which has the effect of separating the « butter » from a cake which is used to make cocoa powder.

And it’s not over… the « kneading » for around twenty hours with a more or less large quantity of sugar, then the « conching » – adding cocoa butter with constant stirring – will reduce the bitterness of chocolate.

Last step. “Tempering”: to become brittle and smooth, the chocolate is maintained at 32°C for molding and coating.

Chocolate is a true emblem of French culinary heritage. But he is threatened.

Since 2003, European legislation has authorized manufacturers to add up to 5% vegetable fats such as palm oil, which allows manufacturers to make enormous savings, the latter costing ten times less than butter. cocoa.

It is up to consumers to choose “real” pure cocoa butter chocolate, produced by good artisan chocolatiers.

Another threat. Global warming which has a direct impact on cocoa plantations. According to some scientists, within thirty years there would be no more chocolate on Earth.

In the meantime, there could soon be a shortage due to the drastic reduction in rainfall in producing countries.

… Foodies and gourmets are very worried…

Copyright©2023 IMPACT EUROPEAN. All rights reserved.

Views: 0

More Stories

Phenom 300E: The World’s Leading Light Jet for 14 Consecutive Years

Art Capital, 20 Years Already

Chers Parents Premieres in Paris